RUGGEDIZED FRAME = RELIABLE ID CARD PRINTER

Ruggedized Printer Frame

In an effort to lower costs, many manufacturers of office products have switched from metal-framed products to plastic. Plastic-framed products are less expensive to source and offer some assembly cost advantages. However, we at IDP do not see those advantages outweighing the benefits of a metal-framed product for higher volume applications.

A ruggedized printer frame offers the following advantages to the owner and operator:

- Better printer quality

- Higher printer throughput

- Longer printer life

- Easier maintenance

- Reduced shipping damage

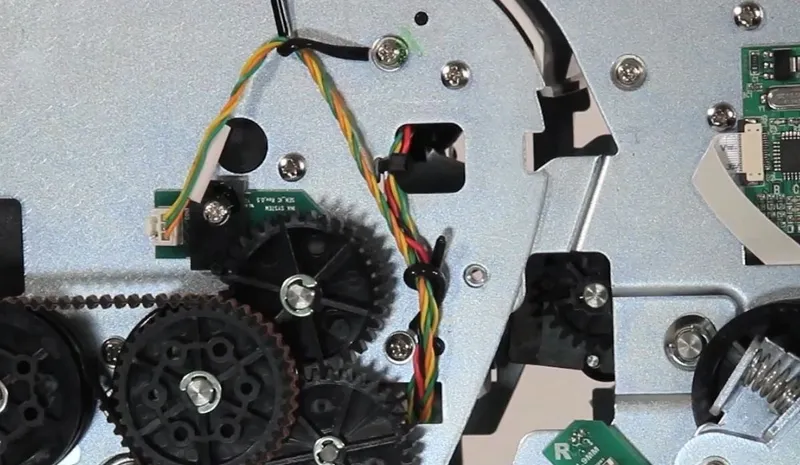

Better print quality – photo id printers use multi-panel ribbons to create up to 16.7million colors. Printer ink ribbons have three color panels – yellow, magenta, and cyan – those three colors must be printed in perfect registration. If a color is off – out of registration with the other colors – by just a tiny bit, the image will look fuzzy and out of focus. A ruggedized printer, like the SMART-51 or SMART-70, controls color registration with optical sensors which control stepper motors that spin card feed rollers attached to a metal printer frame. If the rollers were attached to a plastic frame, eventually the friction of the spinning roller will wear down the frame and the roller will not spin optimally – creating color registration problems. If you have ever had a printer “frame kit” repair on your printer, this is what they are fixing.

Higher printer throughput and longer life – IDP Card Printers are used in many different markets, but one of the most challenging is casino gaming. The IDP SOLID-500OC and SOLID-510OC printers are used to print Player Cards in hundreds of casinos and have printed and magnetically encoded over 100 million cards. It is not uncommon for a casino to print and encode over 100,000 cards on a single printer in just one year. This massive about of printing, with little to no maintenance and repairs, is due to IDP’s ruggedized printer frame. In addition, IDP’s metal-framed printers offer a longer productive life than competitors because of their rugged construction.

Easier maintenance and reduced shipping damage – If you have ever tried to open a modern electronic product, you know that it is full of plastic snaps, catches and guides. These features make the unit simple to assemble at the factory, but very difficult disassemble, repair and reassemble. To make matters worse, many of these plastic parts are single use only leaving you with expensive repair bills. Additionally, these plastic snaps, catches and guides do not ship very well. If a product is dropped or otherwise damaged in shipment, many of those plastic elements will break. Again, leading to delays and expensive repairs.