RETRANSFER ID CARD PRINTER TECHNOLOGY

Retransfer Printing Technology

Digital retransfer printing technology encompasses a number of techniques:

- Impact printers – dot matrix, line

- Non-Impact printers – inkjet, bubblejet

- Laser printers

- Thermal printers – thermal paper, thermal resin transfer, dye-transfer

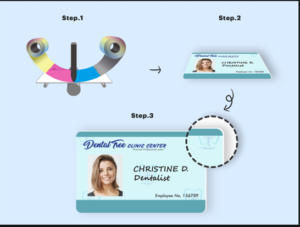

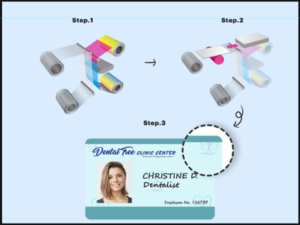

To print a photo identification card on PVC, you’ll use a combination of thermal resin transfer and dye-transfer techniques. Today’s printers typically use a combination ribbon consisting of three dye panels (yellow, magenta, cyan) and two resin transfer panels (carbon black and overlay) – YMCKO. A thermal print head is driven to heat specific pixels (300per inch e.g. 300dpi) which transfer ink ribbon colors onto the card creating an image and text.

There are two printer technologies available to apply the ink to the PVC card – a Direct to Card (DTC) ID Card Printer or Retransfer card printer technology. Both have been around for many years and are highly reliable and produce a very accurate photo reproduction of the card holders image. So, when should you use DTC and RTF printers? Below are the pros and cons of each.

Direct to Card Printing Pros:

- Faster printer cycle time – the printer is ready to print quickly

- Faster print speeds – DTC printers can print a color card in 17 seconds

- Lower cost – most DTC printer hardware and consumables are less expensive

Direct to Card Printing Cons:

- Not over-the-edge printing – printer typically leaves the leading edge of the card unprinted.

- Limited color depth – printing deep dark colors can require excessive heating causing wrinkling or breaking of the ribbon.

- Print head damage – card debris can cause print head scratches, leading to defective prints.

Retransfer Printing Pros:

- HD printing quality – printers, like the SMART-81, offer 600x600dpi printing resolution.

- High gloss rich colors – deep dark colors can be achieved without risk of ribbon wrinkle or breaking. Additionally, printers like the SMART-81 provide a high-gloss finish.

- Over-the-edge printing – printers, like the SMART-81, offer Infinity-edge technology ensuring the entire card surface is printable.

- No print head damage – retransfer technology prints the image onto a film, not a hard card, so there is no risk of print head damage due to debris on the card surface.

Retransfer Printing Cons:

- Slower printer cycle time – typical printers can take up to three minutes before they are ready to print, but IDP’s SMART-81 offers patented “Rapid Retransfer Printing Technology” (RRP) technology that will have the printer ready in only 20 seconds.

- Slower print speeds – the nature of retransfer technology does require a bit longer to print a high quality color card, but typical printers will do so in less than 30 seconds.

- Higher cost – typical retransfer printers are more expensive, but over their life, require less maintenance and produce fewer defective cards requiring reprints.