HOLOGRAM ID CARD LAMINATION TECHNOLOGY

Benefits of Direct Lamination

Laminating a photo identification card is not new. The industry has been laminating an additional layer of film over a cards printed surface since the dawn of the digital card printer market.

This additional layer of film is intended to increase the cards life and its security. Laminate films are heavily tested with agreed upon industry standards to meet the needs of the most demanding applications. Laminated drivers licenses, national ID cards, social services cards and a corporate staff badge all meet the same rigorous testing standards. A properly applied 1mil patch-laminated card can have up to a 5-year card life.

Unfortunately, most suppliers of those “conventional method” ID card lamination machines use outdated, slow and inefficient laminating technology. A laminator requires heat and pressure to effectively adhere the hologram laminate film to the printed card surface. Most suppliers use outdated cartridge, quartz, or halogen lamp heaters affixed inside a metal roller. The heater transfers heat to the roller, the roller then transfers the heat to the surface of the ID card lamination film which activates the adhesive to adhere to the card surface.

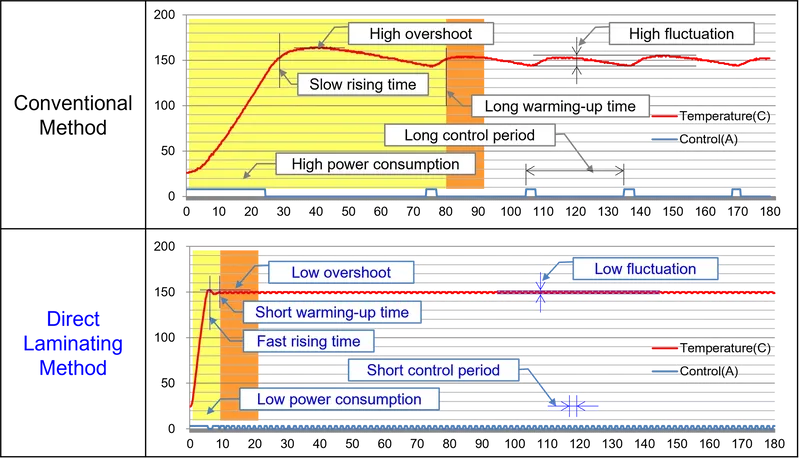

As detailed in graph to the right, the “conventional method” can take up to 3 minutes to get to optimal laminating temperature and that temperature is not held consistently. This can create a weak bond between the card and the laminate film.

The “Direct Laminating Method”, patented by IDP, uses a flat heater affixed to print-head-like mount. This ID card lamination method is capable of reaching the optimal laminating temperature in less than 10 seconds and continues to maintain that temperature evenly to assure complete and consistent bond between the card and the laminate film.

An additional benefit of the Direct Laminating Method includes energy savings. Due to the speed and efficiency of the technology, the Direct Laminating Method will use 7x less energy than the conventional method.

Laminate faster, create a stronger bond, and save energy with IDP’s Direct Lamination Technology, available on the SMART-51L, SOLID-510L, and SMART-70L machines.