Film laminé TECHNOLOGIE

Films de plastification pour cartes d'identité

Laminating a photo ID card is nothing new. Since the advent of digital card printers, the industry laminates an additional layer of film over the printed surface of a card. However, each manufacturer uses their own terminology for film laminates. There are three main types of laminated films used in the industry.

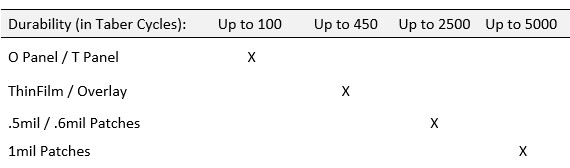

Ribbon overlay : The ink ribbon of the ID card printer has an « O » or « T » panel – YMCKO or YMCKT . This panel O is the base level for the lamination of the maps. During the printing process, the thermal head of the printer transfers the O panel to the printed surface of the card. This very thin layer is intended to reduce board discoloration and dye migration and to provide a low level of abrasion resistance. Below is a durability chart detailing the resistance of the O panel to the Taber test.

Thin Film Lamination: The next step in lamination requires a specialist laminator to apply the film. As on the SMART-51L or SMART-81L, the laminator is attached to the printer, so the process is a one-step process. Click the print button and the system will print and laminate in one go.

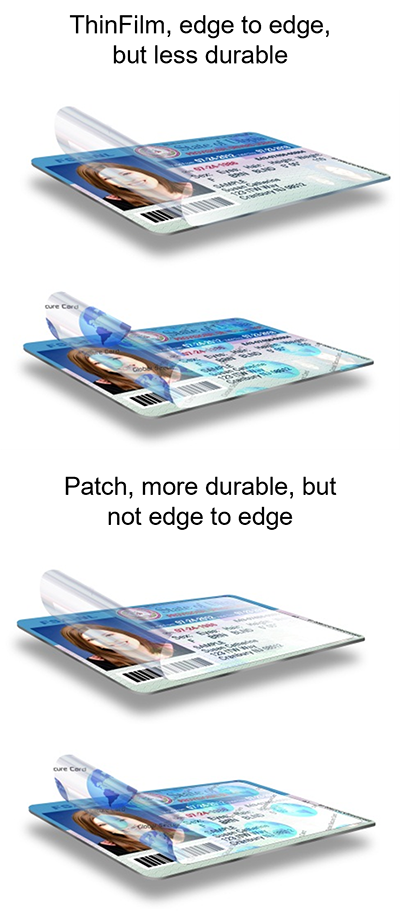

ThinFilm, also called overlay or varnish by other manufacturers, provides an edge-to-edge protective layer covering the entire board. The thin layer can be transparent, providing only protection, or holographic (HRI – what is HRI?) to introduce security features that make it more difficult for ID cards to be counterfeited.

ThinFilm is supplied on 75 mil (19 micron) or 1 mil (25 micron) PET carriers. Holographic or transparent coatings that transfer to the card are very thin, only 0.12 mils (3 microns). This thin layer of varnish increases the card’s ability to resist UV fading and dye migration, but does little to improve the card’s durability.

Patch lamination : Patch lamination also requires a specialist laminator to apply the film to a card, but it offers a much higher level of durability than O-Panel or ThinFilm . A laminated patch increases scratch resistance and card life, and protects against counterfeiting and card tampering. That’s why hundreds of millions of driver’s licenses and ID cards are produced every year using protective film.

Laminates are available in transparent and holographic material (HRI) and in different thicknesses. Patches are available in 0.5 mil (12 microns), 0.6 mil (15 microns) or 1.0 mil (25 microns). The 1.0 mil (25 micron) patch can also be supplied with an additional UV blocking layer upon request to increase card life by reducing fading/crease migration due to direct light from the sun. In general, a 1 mil laminate provides the highest level of durability.

IDP offers many lamination printers and film options. Laminate faster, create a stronger bond to the board, and save energy with IDP’s direct lamination technology , available on the SMART-51L , SOLID-510L, SMART-70L and SMART-81L systems .

Il y a beaucoup à voir ici. Alors, prenez votre temps, regardez autour de vous et apprenez tout ce qu’il y a à savoir sur les produits d’identification avec photo. Nous espérons que vous apprécierez notre site et que vous prendrez le temps de nous écrire.